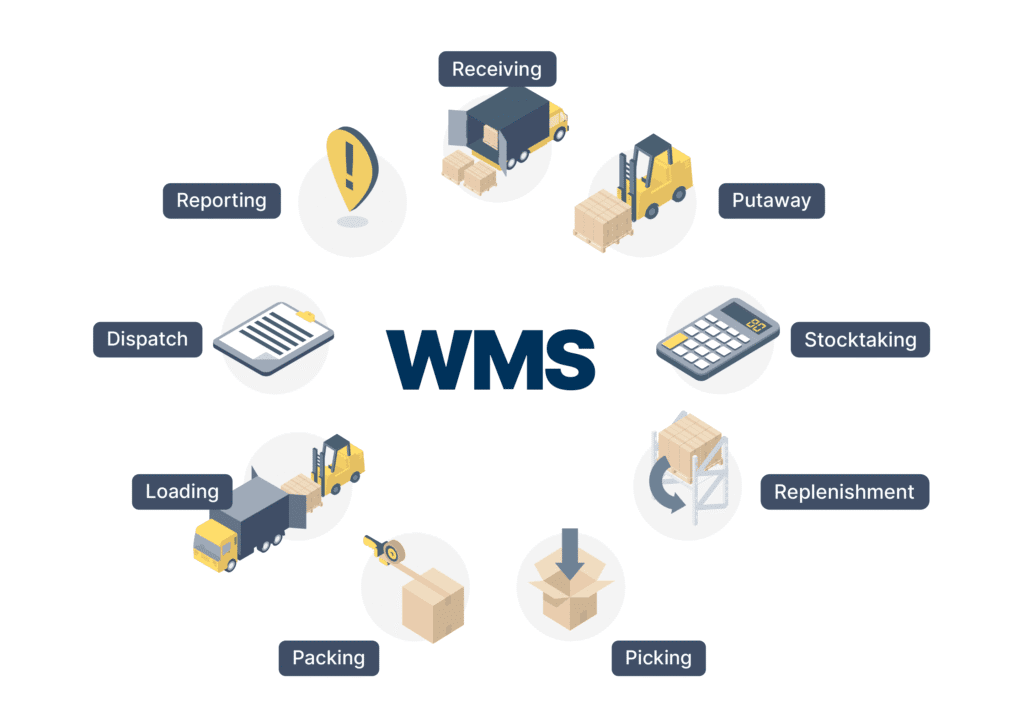

A warehouse management system is a type of software that helps large companies control and manage their warehouse operations. It gives real-time updates on inventory, helps with tracking shipments, and improves overall efficiency. This kind of system is very useful for enterprise companies that manage many products across different locations. With the help of warehouse management software, companies can reduce errors, save money, and improve customer satisfaction.

Step One Understanding Warehouse Requirements

Before starting with a warehouse management system, it is important to understand your company’s exact needs. Every warehouse is different, and the software must match your business type and workflow. Enterprise companies should begin by reviewing their current warehouse operations. They need to identify challenges such as slow order processing, lost inventory, or lack of visibility. This helps in choosing the right features in the warehouse management software that can solve these problems.

Step Two Planning for System Implementation

Once the requirements are clear, the next step is planning the implementation process. This includes deciding which teams will be involved, setting a timeline, and preparing data for the new system. Enterprise-level businesses often have many departments, so the planning process must involve IT, warehouse staff, and supply chain managers. A detailed plan helps to reduce mistakes during the transition and makes sure everyone is ready to use the software when it goes live.

Step Three Selecting the Right Software

Choosing the right warehouse management software is one of the most important steps. The software should be able to handle large volumes of data, support multiple warehouses, and offer real-time tracking. It must also work well with other systems like ERP and order management platforms. Some companies prefer cloud-based systems for flexibility, while others choose on-premise solutions for greater control. The best choice depends on the company’s goals, budget, and IT infrastructure.

Step Four Setting Up the System

After selecting the software, the next step is setting it up for your warehouse. This includes installing the system, connecting it to other tools, and preparing hardware such as barcode scanners or RFID devices. It is important to enter accurate data into the system, such as inventory levels, product categories, and warehouse locations. This setup process takes time but is important for the success of the entire system. Any errors in setup can affect the software’s performance.

Step Five Training Warehouse Employees

A warehouse management system will not be useful if employees do not know how to use it. That’s why training is an important step. All warehouse staff and managers should be trained on how to use the new software correctly. Training should include how to check inventory, process orders, scan products, and generate reports. Good training makes sure employees can work faster and with fewer errors. It also helps them understand how the software supports their daily tasks.

Step Six Testing the Software Functions

Before using the system fully, it should be tested to make sure everything is working as expected. This test phase includes checking inventory updates, order tracking, picking processes, and reporting tools. Enterprise companies often use a pilot test in one warehouse before launching it in all locations. Testing helps find any problems early and allows the team to fix them before they affect real operations. It also helps users feel confident in using the new system.

Step Seven Going Live with Full Use

Once testing is complete and everyone is trained, the system can go live. This means the warehouse management software is now being used as the main tool for all warehouse tasks. It is important to monitor the system closely during the first few weeks. Managers should check for any issues and make sure all users are following the correct steps. This phase is key to a smooth transition and can affect how successful the software will be in the long run.

Step Eight Monitoring System Performance

Even after the software is running, the work is not finished. Enterprise companies should regularly monitor the system’s performance to make sure it is delivering the expected results. This includes tracking key metrics like inventory accuracy, order fulfillment time, and worker productivity. Most warehouse management software includes reporting tools that show these metrics in real time. Regular monitoring helps companies find new ways to improve and grow.

Step Nine Updating and Scaling the System

As a company grows, its warehouse needs may change. That’s why it’s important to update the software regularly and add new features when needed. A good warehouse management system should be able to grow with the business. This includes adding support for more warehouses, new product lines, or different types of inventory. Updating the system ensures that it continues to provide value and keeps up with the latest technology and customer demands.

Conclusion

A warehouse management system is a powerful tool that helps enterprise companies improve control, reduce costs, and serve their customers better. By following a clear step-by-step approach, businesses can successfully implement warehouse management software and achieve long-term success. From understanding needs to going live and scaling the system, each step plays a vital role in making the warehouse more efficient. With the right software and a clear plan, companies can turn their warehouse into a smart, automated part of their supply chain.