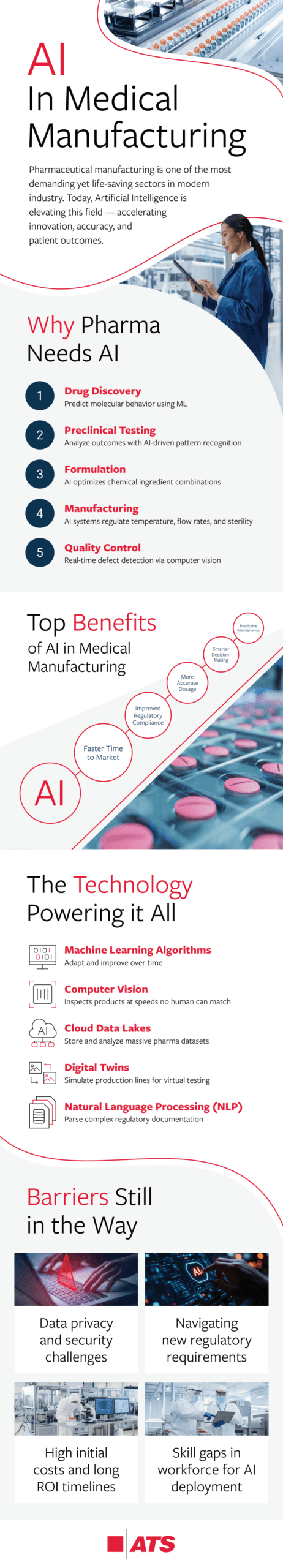

Artificial intelligence is steadily transforming pharmaceutical manufacturing in ways that are subtle but highly impactful. Rather than disrupting operations overnight, AI is being integrated thoughtfully into processes that demand precision, consistency, and strict regulatory compliance. In an environment where even small deviations matter, AI is becoming an essential tool rather than an optional upgrade.

From early formulation through final packaging, pharmaceutical production involves numerous variables. Raw material quality can vary, environmental conditions require constant oversight, and human involvement introduces the potential for error. AI helps stabilize these systems by improving predictability and control. It does not replace human judgment, but instead supports it by delivering clearer insights and more dependable process execution.

Improving Performance Through Continuous Learning

Unlike traditional automation, AI systems are designed to adapt. Instead of following fixed rules, machine learning models analyze data over time and refine their responses as conditions change. This ongoing learning allows manufacturing environments to become more responsive and resilient.

One of the most valuable applications of AI is in process optimization and predictive maintenance. By identifying subtle changes in equipment performance, AI can flag potential issues before they lead to failures. It can also monitor production settings and make real-time adjustments to maintain optimal conditions. These capabilities help reduce downtime, improve batch uniformity, and minimize waste.

AI also strengthens supply chain operations. By examining historical trends alongside real-time data, AI platforms can forecast demand fluctuations, anticipate inventory constraints, and support better planning across global logistics networks. These insights, once difficult to achieve, are now part of everyday operations for manufacturers focused on stability and efficiency.

Balancing Regulatory Demands With Innovation

Pharmaceutical manufacturing operates under strict regulatory oversight, which is essential for ensuring safety and quality. At the same time, these requirements can slow modernization efforts if not managed carefully.

AI offers practical support in this area by reinforcing compliance while enabling innovation. Tools such as natural language processing help teams review and interpret regulatory materials more efficiently, while advanced data tracking enhances traceability throughout production. These capabilities allow manufacturers to implement new technologies with confidence and control.

As AI continues to mature, its role in medical manufacturing will expand further. The focus is not on chasing trends, but on building reliable systems that support consistent, high-quality production.

For additional perspective on how AI is shaping pharmaceutical manufacturing practices, refer to the accompanying visual resource from Advanced Technology Services, a provider of industrial maintenance services.